SERVICES

Rapid Prototyping and Production Machining

Our state-of-the-art CNC milling centers are equipped to handle both large and small production runs with precision and efficiency. Capable of machining parts up to 55 inches, our machines are designed to deliver exceptional accuracy and maintain reliable tolerances every time. Whether you're developing new products or need consistent production for your existing designs, we have the tools and expertise to bring your vision to life with precision and reliability.

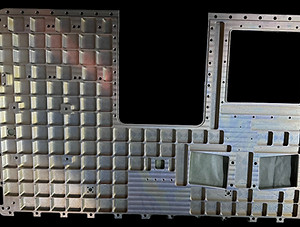

Specializing in machining thin material and Plate: Aluminum and Plastics

We specialize in large flat plate work with our advanced Datron M8Cube machining center. This high-performance machine is specifically designed for precision milling and delivers exceptional results on aluminum, plastics, and other materials. Utilizing a state-of-the-art vacuum workholding system, we can securely hold large, flat parts for highly accurate machining. In addition to handling large plate work, the Datron M8Cube excels at micro-machining, allowing us to produce intricate details and features with unmatched precision. This combination of capabilities makes us the go-to choice for projects requiring both versatility and accuracy.

Design/Engineering

We specialize in assisting with part design and engineering, helping you turn your ideas into reality. Whether you have a detailed concept or just a rough sketch, our team can guide you through every step of the process to develop your idea from the ground up. From initial design and prototyping to final production, we provide the expertise and resources needed to create a fully engineered and realized product that meets your exact specifications

Gear Cutting

We have the capability to precision-machine a wide variety of gears on our multi-axis CNC machines, serving industries such as aerospace, automotive, and defense. Our expertise includes producing worm, helical, double helical (herringbone), rack, bevel, and spiral gears, among others.

We work with a range of materials, including steel, copper, bronze, aluminum, and various plastics, ensuring we can meet the specific requirements of your application. Whether you need gears for high-performance systems or specialized prototypes, our advanced CNC technology delivers exceptional accuracy and quality for every project.

Finishing Service and Plating

We offer the following finishing and plating services:

Type II and III Anodizing

PTFE impregnated Anodizing

Bead Blast

Nickel Plating

Chem-film

Electropolich

Passivation

Inspection

In addition to our reverse engineering capabilities, we offer comprehensive CMM and inspection services to ensure the highest level of accuracy and quality for your machined parts. Our inspection processes adhere to AS9100D and ISO9001 standards, giving you confidence in the precision and reliability of every part we produce.

Using our state-of-the-art laser CMM machine, we provide highly accurate measurements and detailed inspection reports tailored to your project requirements. These reports document every critical dimension, ensuring your parts meet the most stringent specifications. Whether you need first-article inspections, in-process verifications, or final part validation, our advanced inspection capabilities guarantee exceptional quality control at every stage.

ABOUT

Precision CNC Machining Services with a Personal Touch

At our family-owned Montana machine shop, we don’t just make parts — we solve problems. Whether you're facing tight deadlines, struggling with difficult-to-machine materials, or need high-quality prototypes to kickstart your project, we’re here to help.

As a local business, we take pride in offering the personalized service and craftsmanship you’d expect from a family-run operation. We specialize in machining aluminum and plastic large flat parts, micro-machining, and handling both high-volume production runs and low-quantity prototype jobs. Additionally, we manufacture custom tools for aircraft, with a focus on the UH-60 Black Hawk helicopter, providing mission-critical support to aerospace and defense operations. No matter your challenge, we work closely with you to ensure your parts are delivered on time, meet your specifications, and exceed your expectations.

Common Challenges We Solve for Our Customers:

✅ Tight Timelines? We excel at rush and emergency jobs.

✅ Need precision with tough materials? We’re experts in titanium, stainless steel, copper, brass, aluminum, and plastics.

✅ Struggling with complex designs or prototyping? Our team brings your vision to life with precision and care.

✅ Need reliable, high-quality production? From short runs to high-volume production, we’ve got you covered.

✅ Require specialized aircraft tools? We design and manufacture custom tools specifically for the UH-60 Black Hawk and other aerospace applications.

Our Capabilities Include:

✔ Short & Long Production Runs

✔ Prototyping

✔ Large Flat Part Machining (Aluminum & Plastics)

✔ Micro-Machining

✔ Fixture Design

✔ Mold Cavity Machining

✔ Mold Base Plate Design & Machining

✔ Custom Aircraft Tooling (Specializing in the UH-60 Black Hawk helicopter)

✔ Assembly & Secondary Operations

✔ Rush/Emergency Jobs

With advanced equipment, skilled machinists, and a commitment to excellence, we treat every project like it’s our own. As a family business, we understand how important it is to deliver precision, quality, and reliability every time.

Let us show you why customers trust us as their go-to Montana machine shop. Partner with us to tackle your machining challenges — so you can focus on what you do best.